The welding repair of cold stamping die is a kind of functional welding, which is not only a simple repair of defects, but also to make the welded deposited metal (weldment) have toughness, wear resistance, crack resistance, impact resistance, smooth surface and anti galling. Choosing the matching welding materials, adopting the correct welding process and controlling the production of welding defects can greatly reduce the cost of mold manufacturing and use, and improve the efficiency of enterprises.

Brief table of welding materials for stamping die

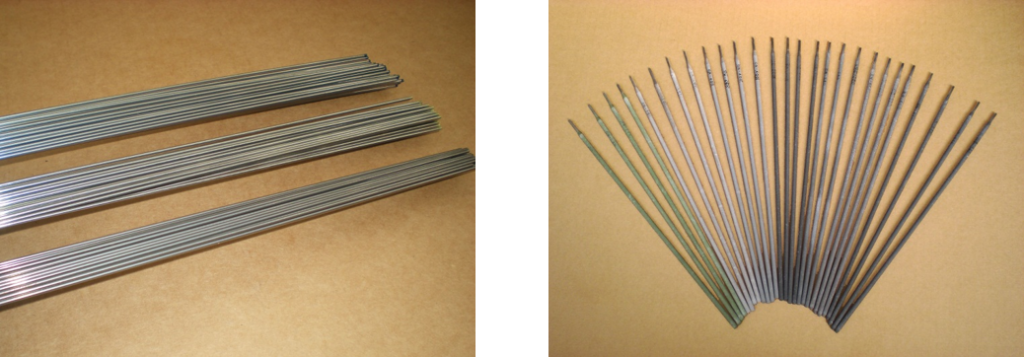

Purpose | Characteristic | Welding rod | Flux cored wire | TIG welding wire |

| Cast iron surfacing | 55%Ni-Fe Composite core wire | 550 | 550S | 550T |

| Direct hardfacing of cast iron | HRC 55-60 | 580 | 580S | 580T |

| HRC 47-53 | 500 | 500S | 500T | |

| HRC 45-50 | 400 | 400S | 400T | |

| HRC 20-30 | 200 | 200S | 200T | |

| Composite hardfacing of cast iron | For priming | 400 | 400S | 400T |

| For covering | 610 | 610S | 610T | |

| Air cooled steel | HRC 55-60 | 600 | 600S | 600T |

| Cr12MoV and other tool steels | HRC 55-60 | 610 | 610S | 610T |

| HRC 60-63 | 900 | 900S | 900T | |

| Anti galling surfacing | Special bronze welding materials | 8CU | 8CUS | 8CUT |

| Dissimilar metal connection | Universal metal connection welding material | 299 | 299S | 299T |