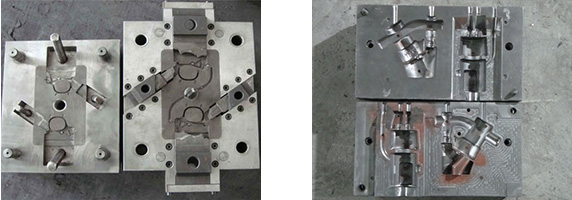

Die casting mold welding materials are suitable for die casting mold manufacturing and maintenance, production equipment maintenance, casting product repair and so on. Welding materials have a complete variety and excellent quality, which can greatly prolong the service life of molds and equipment and significantly reduce the production cost of enterprises.

Brief list of welding materials for die casting die

Designation | Hardness after welding(HRC) | Application and performance |

| 61T | 51-55 | After welding, it has the same composition as H13, SKD61 and other hot work die steels, and has good wear resistance, crack resistance and high temperature resistance |

| 45T | 45-49 | The hardness is moderate after welding, stable after high temperature, and can be nitrided |

| 299T | Low | Excellent fusion, crack repair, welding wire for universal connection of dissimilar metals |

| 1T | After welding: 35 Aging treatment: 50 | Special welding wires with high content of Ni, CO and Mo have low hardness after welding, increased hardness after aging treatment, and excellent wear and crack resistance |

| 100T | Low | Pure Ni welding wire is suitable for the connection and repair of various cast iron |

| 620T | 38-40 | Cobalt free, excellent heat cracking resistance and solution damage resistance, significantly improving the service life of aluminum die-casting hot work abrasive steel |